🏠 Balloon Frame System: How Prefabricated Wooden Houses Are Built

🏠 Balloon Frame System: How Prefabricated Wooden Houses Are Built

The balloon frame system in prefabricated wooden houses is a construction method that uses lightweight wooden frameworks to create a structural skeleton for walls and cladding. Originating in the United States, this technique has been widely applied for decades in single-family homes. Over time, it has evolved into an efficient, fast, and sustainable building solution across Europe, where nearly 90% of prefabricated wooden houses are now built using this light wood framing approach.

If you want to learn more about this type of home, check out the Vilssa article on truths and myths about prefabricated wooden houses.

🪵 Features of the Balloon Frame System

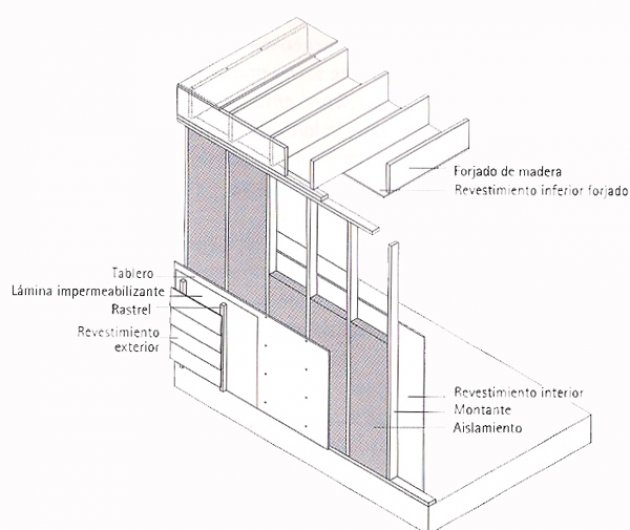

The Balloon Frame System consists of a lightweight timber framework with cross-sections between 30 and 80 mm, placed less than one meter apart and braced with structural boards or strips. Together, walls, floors, and roofs form a unified spatial structure connected with screws or nails for strength and stability.

The foundation design depends on the type of soil. In most cases, reinforced concrete slabs or platforms are used as a solid base that supports the timber framework of the ground floor.

🏗️ Building Envelope in the Balloon Frame System

When it comes to the exterior shell, most prefabricated wooden houses use envelopes made of wooden strips, panels, or boards. Some versions employ sandwich panels composed of two solid wood sheets with an insulating thermal core. Others are built directly on-site, where insulation is placed between the wooden studs, and both the interior and exterior surfaces are finished with wooden cladding.

🌡️ Advantages of the Balloon Frame System

- ♻️ Thermal efficiency: Wood has a low thermal conductivity, helping maintain a stable and comfortable indoor temperature.

- 🚫 No thermal bridges: Because both the structure and cladding are made of wood, heat loss through structural breaks is minimized.

- ⚙️ Fast and sustainable: The dry construction method reduces building time and minimizes CO₂ emissions during assembly.

🔥 Disadvantages of the Balloon Frame System

- 🔥 Fire protection: Due to the small thickness of the wooden studs, they must be covered with fire-resistant materials or coatings.

- 🧱 Maintenance: Periodic inspections are essential to ensure protection against moisture, UV exposure, and insects.

🏡 Prefabricated Wooden Houses and Other Systems

Many people associate prefabricated wooden houses with the Balloon Frame system, but there are several alternative methods that also use timber as the main material.

- Heavy timber frame: Based on large-section wooden beams and columns forming a robust structural frame.

- Cross-laminated timber (CLT) panels: Structural wood panels used as load-bearing walls and floors, offering excellent rigidity and insulation.

To explore more about different types of prefabricated wooden houses, visit Vilssa’s dedicated section on wooden architecture.