Concrete Façade Panels with Internal Insulation: How They Work

How concrete façade panels with internal insulation work

Precast concrete façade panels with internal insulation are a reliable industrial building solution. They combine strength, thermal performance, and fast installation. Moreover, they meet common building regulations and technical requirements.

General principle of insulated concrete façade panels

First of all, these panels include a continuous insulation layer inside the concrete. As a result, heat losses are reduced while structural strength is maintained.

Technical summary of insulated façade panels

| Feature | Typical values |

|---|---|

| Total panel thickness | 20 – 30 cm |

| Internal insulation thickness | 3 – 15 cm |

| Standard width | 2.5 m |

| Maximum length | 12 – 14 m |

| Installation position | Horizontal or vertical |

| Structural use | Façade enclosure and load-bearing element |

Panel composition and design

- 🧱 Understand the panel composition

First, the panels are made of precast reinforced concrete. They include a continuous internal insulation layer. Therefore, the overall weight is reduced and thermal performance is improved. According to ANDECE, this system improves the global behaviour of the façade. - 📐 Adapt thickness to insulation requirements

Next, the total panel thickness usually ranges from 20 to 30 cm. The internal insulation layer varies between 3 and 15 cm. This flexibility allows the panel to meet specific thermal requirements. - 🔩 Ensure structural rigidity

In addition, the panels include longitudinal stiffening ribs. These elements reduce deformation during transport and installation. Transverse reinforcements further increase mechanical strength. - 📏 Optimize panel dimensions

In practice, standard panel width is 2.5 m. Maximum length reaches 12 to 14 m. As a result, the number of façade joints is reduced. - 🧩 Define installation system and joints

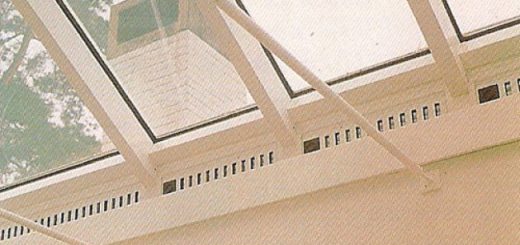

Panels can be installed either horizontally or vertically. Connections are made using tongue-and-groove joints. Consequently, alignment and airtightness are ensured.

Installation and finishes

- 🎨 Select suitable exterior and interior finishes

Exterior finishes can be smooth or textured. Exposed aggregates are also possible. Inside, mechanical trowelling allows direct painting without additional plastering. - 🏗️ Use special prefabricated elements

Many manufacturers offer special components. These include curved corners and preformed openings for doors and windows. Thus, on-site work becomes more accurate. - 🏢 Use panels as load-bearing elements

However, structural use requires precise load calculations. Even so, this solution can significantly reduce the main building structure. - 🔍 Compare with other façade systems

Finally, it is useful to compare this solution with other industrialized systems. For example, polymer concrete ventilated façades can be an effective alternative depending on the project.

Content written by the editorial team of construccion.vilssa.