Stretch Vinyl Ceilings: What They Are, Features, and Advantages

Stretch Vinyl Ceilings: What They Are, Features, and Advantages 🏠

Stretch vinyl ceilings are a modern and versatile decorative solution made from vinyl or PVC.

These plastic ceilings are mainly used for aesthetic purposes, as their elastic material allows a wide range of color, shape, and texture combinations that can be adapted to any interior design.

🧩 Composition and Manufacturing

The main component of these ceilings is a flexible polyvinyl chloride (PVC) sheet, sometimes made from several sections welded together by heat.

Each sheet is manufactured to order according to the project design, allowing combinations of different colors, shapes, and finishes.

The result is a seamless, elegant, and fully customizable surface.

🧱 Supporting Structure

Installing a stretch ceiling requires a support structure, which can be made of metal, wood, or PVC.

Its function is to hold the desired shape of the finished ceiling.

Lighting fixtures, speakers, air vents, and even smart-home systems can be integrated into the design, making it both functional and decorative.

💧 Main Features

Thanks to the properties of PVC, stretch ceilings offer remarkable advantages:

1️⃣ Waterproof. Perfect for humid environments such as bathrooms and kitchens.

2️⃣ Fire-resistant. The material is flame-retardant and safe for interior use.

3️⃣ Design versatility. Available in curved, glossy, or matte finishes in many colors.

4️⃣ Quick and clean installation. No major construction required, adaptable to existing structures.

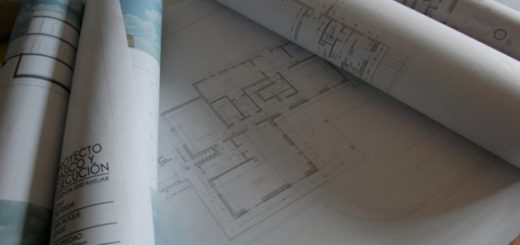

⚠️ Disadvantages and Precautions

The main drawback is their fragility against cuts or impacts.

Additionally, these ceilings offer limited access to hidden installations such as electrical or HVAC systems.

For this reason, it’s essential to carefully plan the design during the project phase to avoid future maintenance issues.

📐 Technical Specifications

- Calendered polyvinyl chloride (PVC) sheet.

- Semi-rigid PVC harpoon obtained by extrusion.

- Rigid vinyl or aluminum profile, extruded and internally milled.

- Thickness: 0.16 to 0.19 mm.

- Approximate weight: 180 g/m².

📎 More Information and Resources

For more technical details and design inspiration, visit:

Written by the Vilssa construction and renovation editorial team.